The aviation sector must decarbonise by 2050

Flying is the most carbon-intensive mode of transport. Yet no practical and scalable emission-free options exist to decarbonise by 2050 (IATA Net Zero). Airlines are also extremely cost-sensitive, with an average profit margin of only 2.7% in 2023.

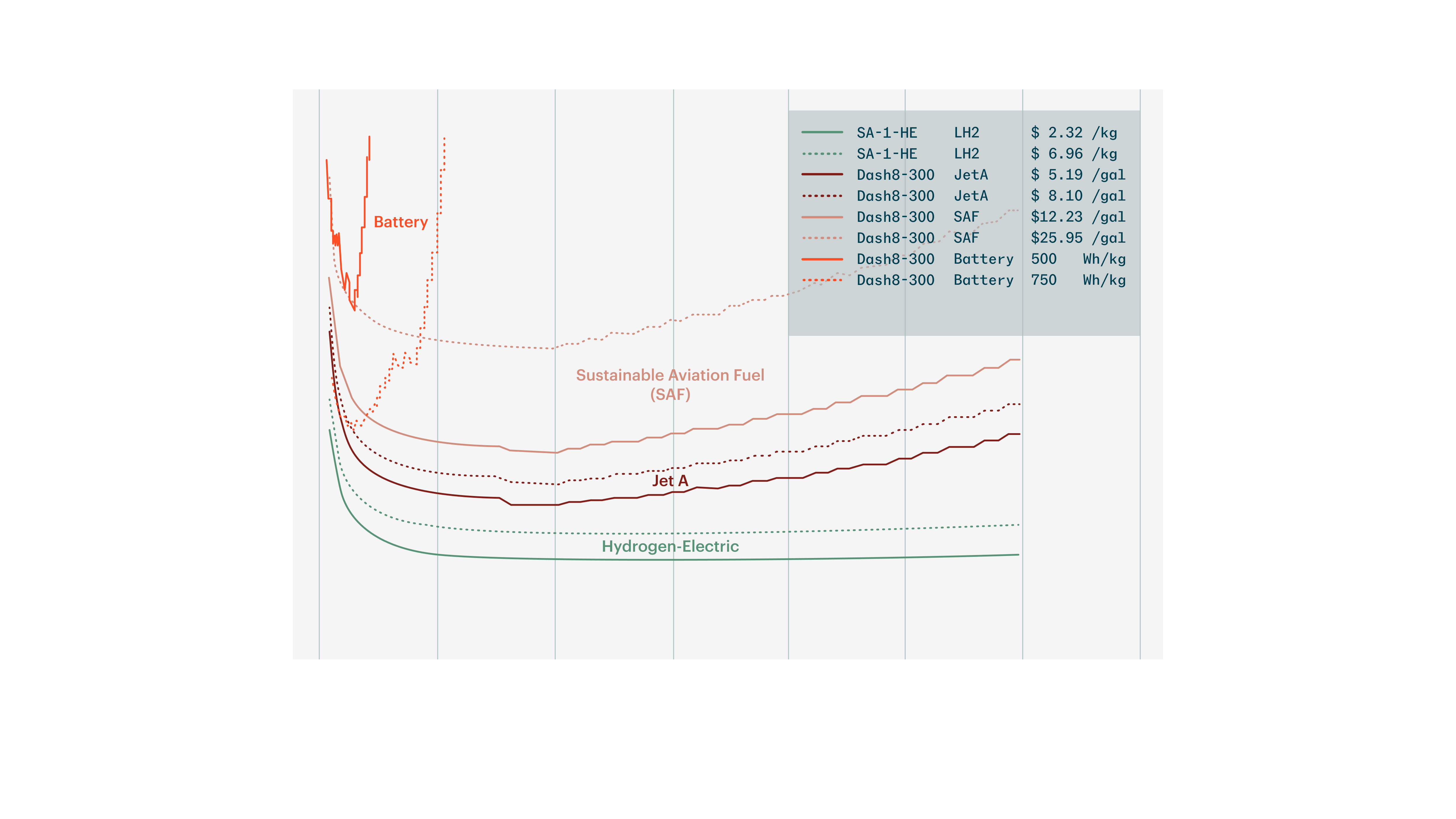

Most major airline roadmaps only focus on Sustainable Aviation Fuel (SAF) which is a costly and partial solution. Other hard-to-abate sectors where batteries aren't effective urgently need alternatives. Current alternate flight solutions, such as batteries and SAF, compromise on emissions, payload, range, and cost.

SAF is expensive at approximately 4-8x the cost of fossil fuel. It emits tailpipe carbon dioxide, NOx, sulphates, and particulates (soot). This presents significant challenges related to scale and carbon capture.

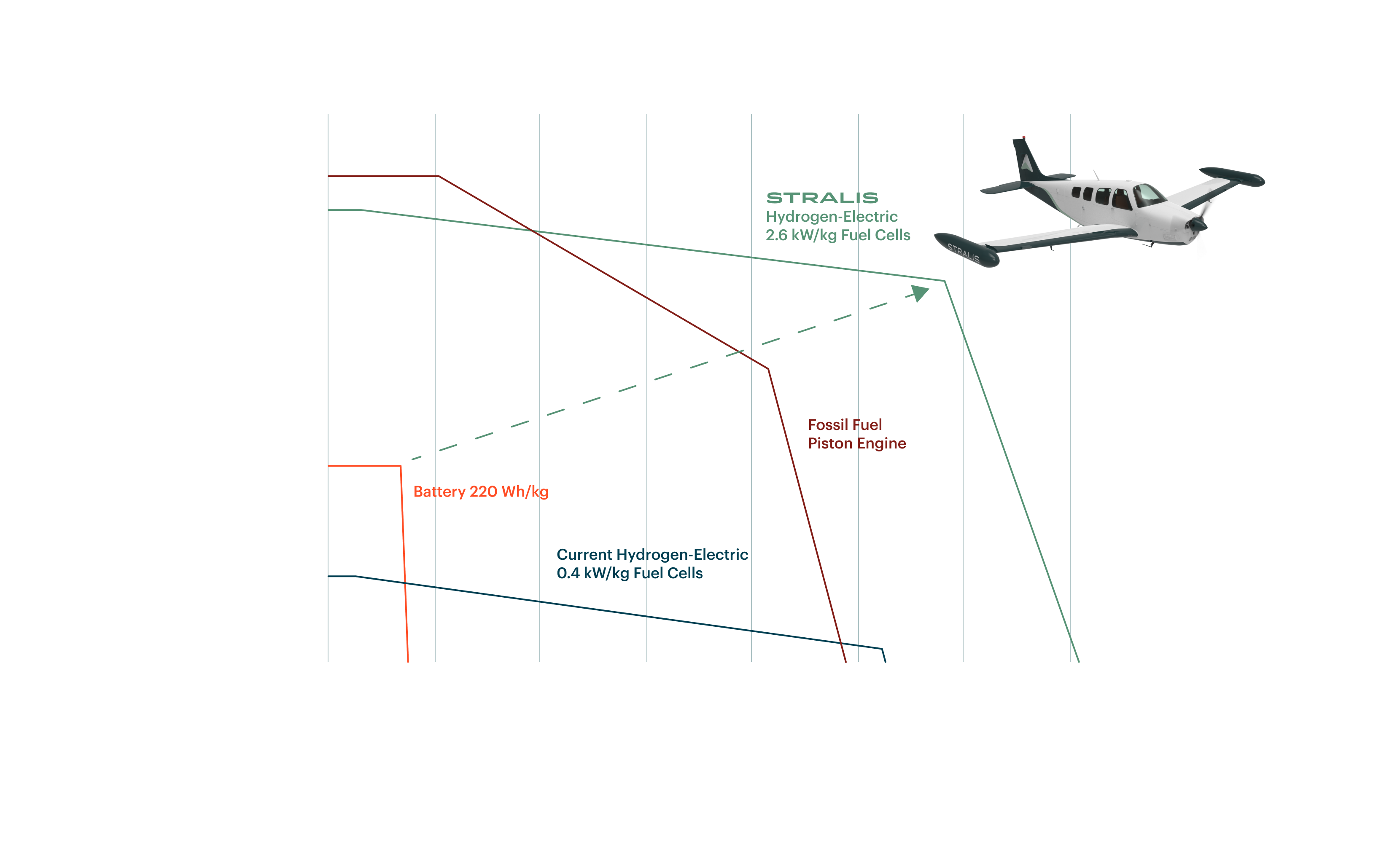

Even with the latest battery breakthrough of 500Wh/kg the range is too short. Due to cycle life limitations, replacement costs are high. Turnaround times are too long due to slow charging. Battery hybrid systems are complex, with high costs and minimal emission reduction.

Stralis hydrogen-electric propulsion (HEP) will be the lowest cost emission-free option

Cost per Available Seat Kilometer (CASK) Comparison in 2035. Battery vs. Sustainable Aviation Fuel (SAF) vs. JetA vs. Hydrogen Electric.

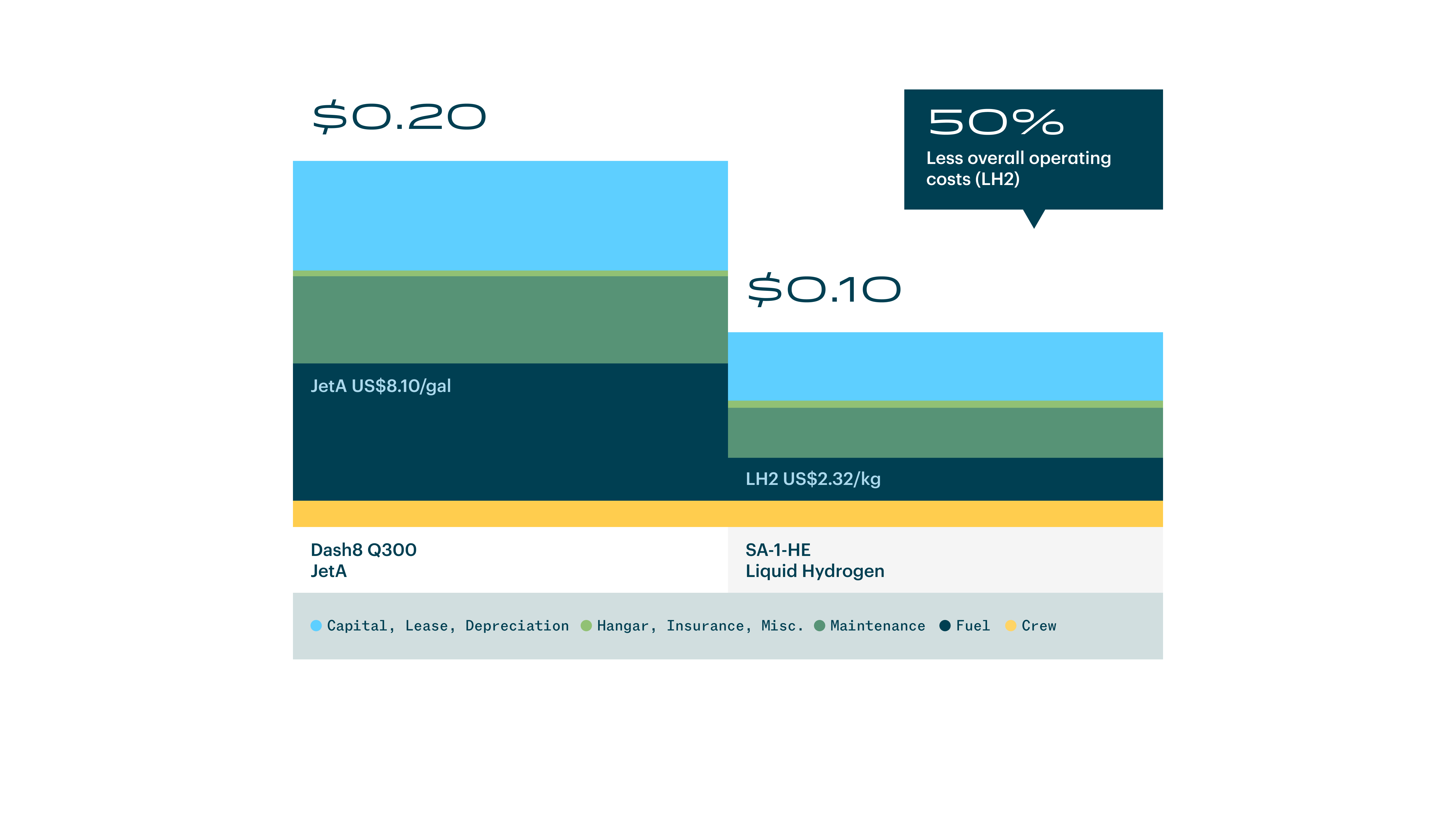

Hydrogen-electric operating costs are reduced due to savings on engine maintenance and fuel

Low maintenance cost

An estimated 60% reduction in engine maintenance costs compared to turbines.

Fuel savings

Low fuel costs compared to jet fuel and Sustainable Aviation Fuel (SAF) used in turbine engines.

Useful range

Unlike battery electric, HEP delivers ranges suitable for commercial, regional routes.

Local fuel production

Green hydrogen can be produced onsite and locally at a range of scales.